CNC stands for Computer Numerical Control, and it’s most commonly used in the manufacturing industry.

Swiss CNC machining is a machining process also known as “sliding head stock” where the bar moves in addition to the tools. They use computer software to control the movement of axis and tools within the lathe. CNC processes are highly effective for controlling tools to precise dimensions when cutting metals and making machined parts.

What is CNC Machining?

CNC machinery combines sophisticated computer software with compatible manufacturing tools and machinery. The computer software controls and guides the machinery to complete specified tasks, similar to a robot.

Machinists used to program machines using paper punch cards which would then be fed into the machines. The machine would read the dimples on the cards and tools would move according to the dimples. Now a G and M code language, combined with coordinates, is entered into the computer on a machine. The machine reads the program and tools move according to the codes and coordinates. The output is a very precise process that can hold dimensions to a fraction of a hair. Once the machine is programmed, the software will run independently, enabling operators to move on to other tasks.

What Are the Benefits of CNC Machining?

CNC machining enables manufacturers to automate some of their processes by removing the need for manual control. The CNC software guides the manufacturing tools through a set of prompts. The integration of CNC machines reduces stress on operators and speeds up efficiency and productivity for manufacturers.

Automation via pre-programmed software ensures consistency, reliability, and accuracy in a way that manual work cannot. Manufacturers can rest assured knowing that they can trust their software to guide their machinery in a specific way to achieve the desired outcome every single time.

CNC Software and Programming

All types of CNC manufacturing use software-guided machinery. The programming language that developers use for CNC machining is known as G-code, and it coordinates the speed, directions, and feed rate of the manufacturing tools.

Once coded, the software can run independently without requiring human intervention. However, operators will usually run a test once the software is ready to ensure that there are no errors or glitches.

There are two main processes that manufacturers use in CNC machining – open-loop and closed-loop. The former refers to when the signal between the control unit and the motor is unidirectional.

Closed-loop systems involve bidirectional communication between the controller and the motor of the machinery. This type of system offers more resilience and versatility, as the control unit can receive feedback and rectify small errors during the process itself.

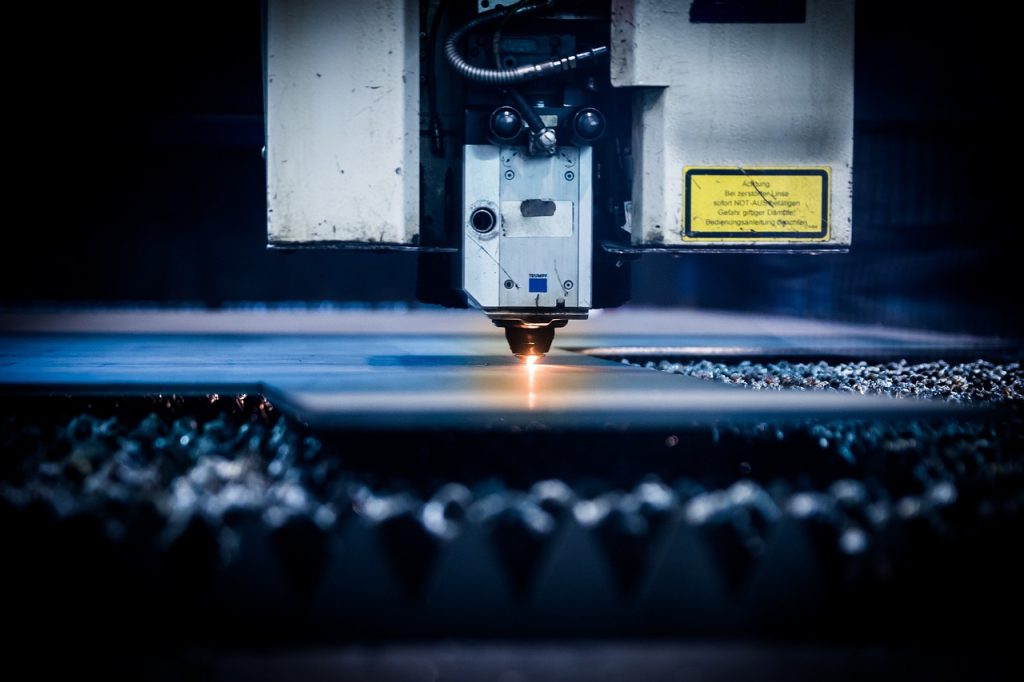

CNC Machinery and Tools

CNC machines can combine the benefits of multiple tools to provide fast but precise production of materials, including:

- Electric discharge machine – an EDM uses electrical charges to break apart conductive materials.

- Lathe – a tool that cuts rounded shapes along two different axes.

- Mill – a tool used to form complex components using three to five axes.

- Plasma cutter – a tool that uses electrical arcs and combines them with compressed air to produce a plasma torch. The plasma torch is then used for cutting hard metals with high speed and accuracy.